Études de cas

Nul besoin de nous croire sur parole — lisez plutôt les témoignages de nos clients sur leur expérience de collaboration avec nous.

The proven solution for addressing our top industrial needs

Medical

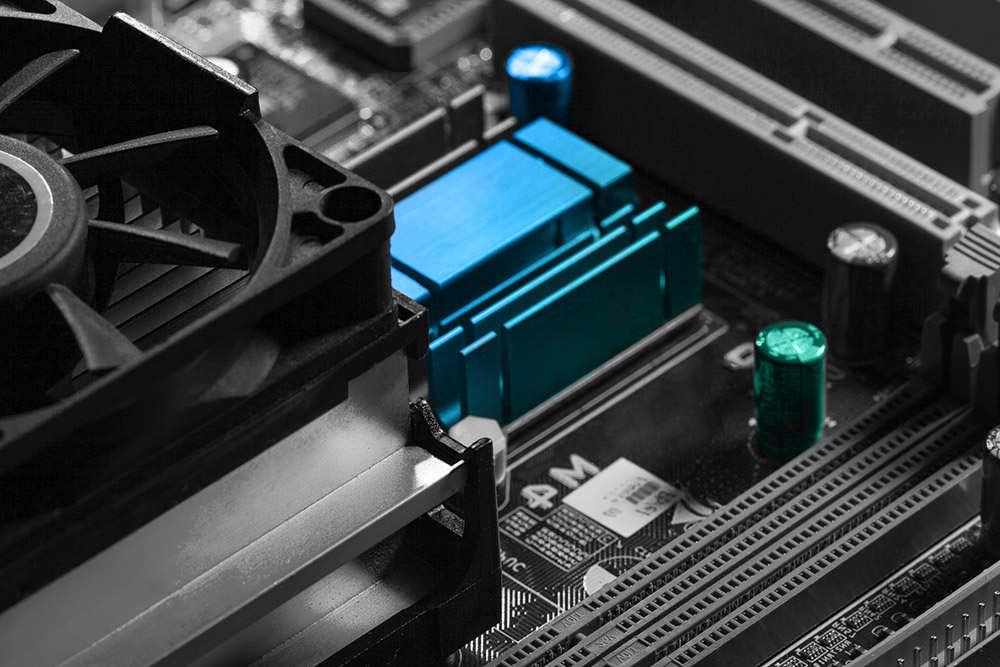

Electronics

Automotive

« We are now able to make more than twice as many parts in the same amount of time—one process part output increased from 16,000 to 40,000 parts per day. »

Christopher Weaver

Project Engineer, FLEXAN LLC / MEDRON LLC

Voir les solutions

« The first indication of return on investment was the cycle time improvements, followed by the definition and standardization of the molding process and quality improvement. »

Jose Bando Huerta

Mechanical Process and Molding Engineer, Bosch

Voir les solutions

« Our scrap went from 1.25% to .25%, and our daily output went from 99,000 connectors to 150,000. »