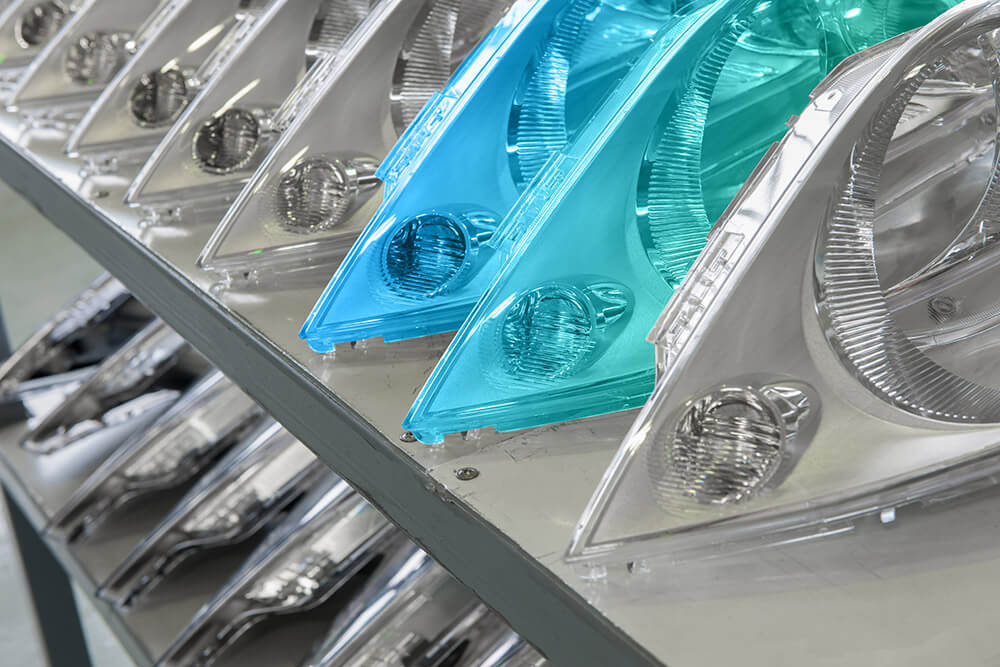

Technologie innovante, formation et services de conseil, de la conception à la production.

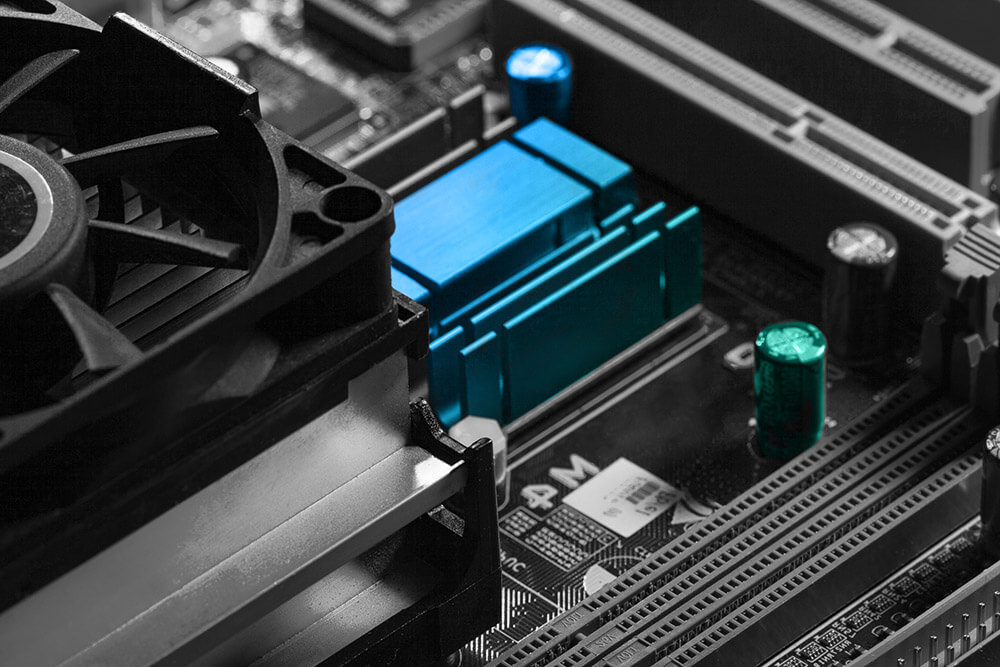

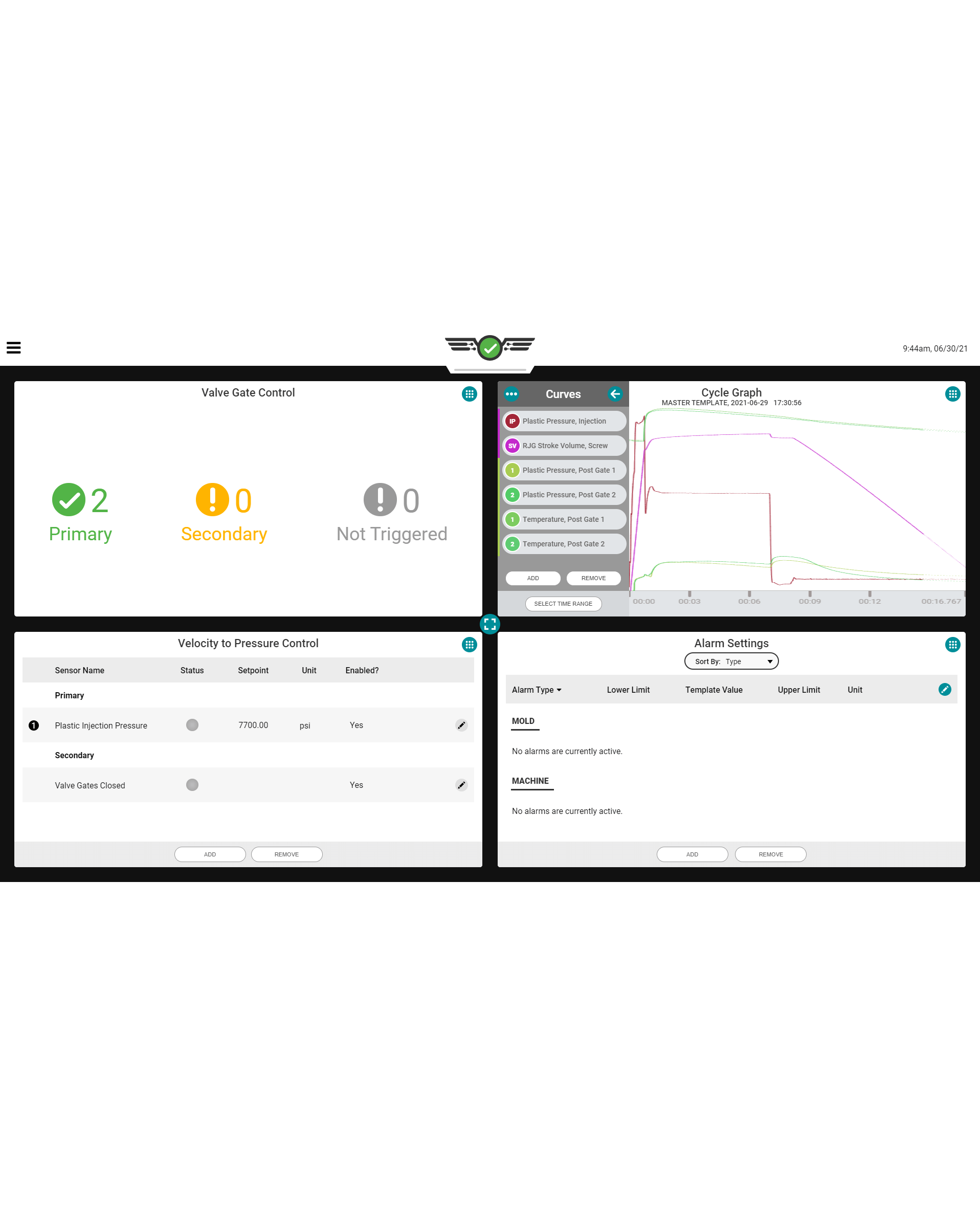

Technologie

Bénéficiez d’un avantage concurrentiel grâce au tout dernier logiciel de pilotage du process du secteur en gagnant en productivité, en réduisant les déchets et en améliorant la rentabilité. Nos solutions technologiques complètes personnalisées sont conçues pour relever vos défis du quotidien.

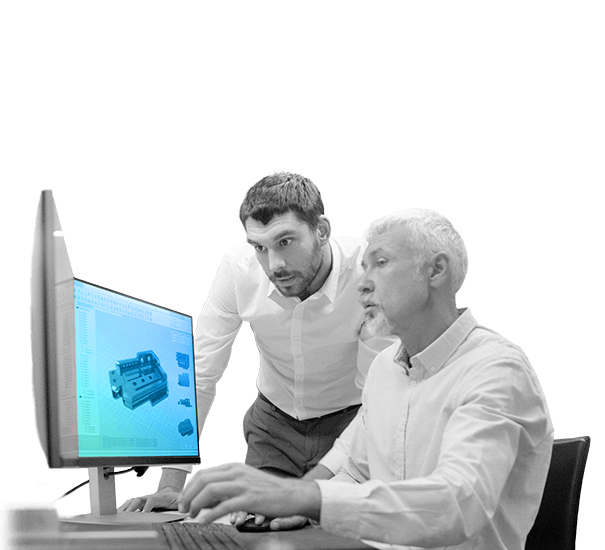

Formation

Un personnel formé a pour effet d’améliorer la qualité des produits, l’efficacité, le moral et le chiffre d’affaires. Nos formations en ligne et en présentiel proposées partout dans le monde sont délivrées par des spécialistes du secteur dotés d’une expérience pratique du moulage par injection et sont adaptées à vos besoins spécifiques.

Conseil

Tirez profit de l’expérience étendue de nos consultants pour dénouer des problèmes persistants dans des processus déjà établis. Réduisez les déchets de l’art à la pièce grâce à des lancements d’outils simplifiés vous permettant de fabriquer de bonnes pièces dès le premier coup.