Tip of the Day 114: Check Screw Overshoot on Fill-Only Parts

Here is a suggestion for a very simple check of your press’s ability to transfer when you are making a fill only part:

When making a fill-only part (hold turned off), compare the transfer position setting on the press controller with the maximum screw forward position. Any difference is screw overshoot. The larger the difference the greater the fill-only part size will be compared to the volume injected when the screw is stopped (or slowed) by hold pressure.

On the eDART™ you can compare the two values: Value at V1->V2 Transfer / Shot Volume and Peak / Shot Volume. « V1->V2 » is the end of the eDART‘s Machine Sequence / Fill signal. This is normally set with fill volume or, of the fill volume is not set, peak injection pressure.

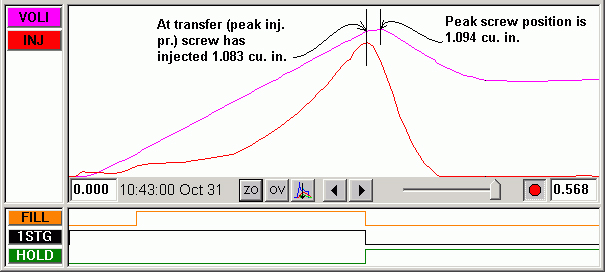

Here is an example of a machine with very little overshoot (about 1%):

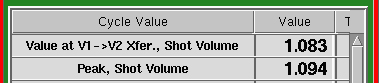

The Cycle Values would look like this. The difference in the two values is the overshoot:

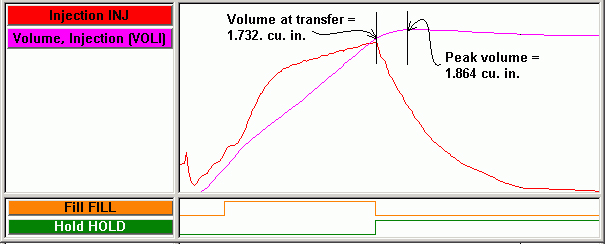

Here is an example of a machine with much more overshoot (about 8%) due to the slow decay of injection pressure.

The cycle values on the eDART can also be used and read like this:

As mentioned in the previous two tips (Tips 112 & 113), the main point is to know your machines. If you try to transfer a mold between the two machines above and you make the same size (or weight) fill-only part on each you may get quite different processes when the hold pressure is applied and the extra screw motion does not occur on the second machine.