Tip of the Day 110: Reaction Time to Analog Cavity Pressure Signals

To reduce the press and eDART™’s reaction time (details defined below) to the minimum for high-speed molding on some presses it may be best to use an analog output from the eDART wired to the press’ cavity pressure signal input.

Some machines have both an external transfer input (from an OR2-D contact closure) and an analog input into which you can put a cavity pressure signal voltage (0 – 10V). The eDART can drive either type of output to transfer the press: contact closure or analog output.

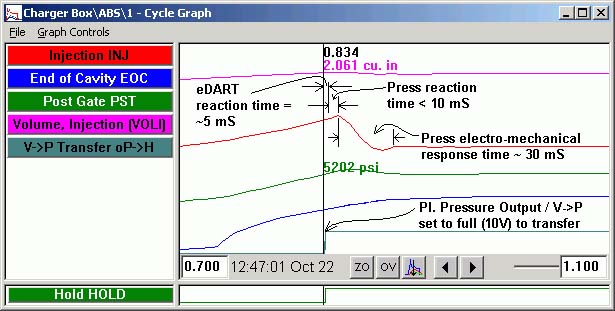

We have found that some machines « scan » (i.e. « pay attention to » or « react to ») the analog cavity pressure sensor signal faster or more often than they do the contact closure signal from the OR2-D. In one case we noticed that when we used Control Output / V->P Transfer on an OR2-D to transfer the press the press reaction time was about 20 mS. When we used an AO1-D analog output signal set up as Plastic Pressure Output / V->P Transfer† the reaction time of the press was less than 10 mS. Some presses may even react with with no measurable reaction time delay, if they have a fast controller.

A little of this can be attributed to the actual time that the OR2-D takes to move his contacts from open to close (about 3 mS). The analog output is electronic and does not included this time. But we think the remainder is due to scan time on the press. Some presses seem to scan the contact closures less often than the analog signals.

† The eDART drives its Plastic Pressure Output / V->P Transfer from 0 to 10V at transfer. The press controller is then set with almost any cavity pressure transfer threshold.

Defining Reaction and Response Times

From tip# 109 remember that there is a delay in the press’ ability to react to a signal from the eDART. The eDART also has a slight delay in getting the physical value of the cavity pressure in, making a decision and sending the signal back to the press to transfer. I have used « reaction time » for these delays. In electromechanical systems like an injection molding press the time to do something after the actuators actually actuate is sometimes called « response » time. While trying not to confuse the issue too much let’s define the following:

-

-

« Reaction Time »: Time for a controller to react to a signal and pass a command to an actuator. The eDART has a reaction time (from cavity pressure to OR2 contact closure) and the press has its own reaction time (OR2 closure to beginning physical action).

-

-

-

« Response Time »: Time from when the actuator fires until the press physically completes its response (stops moving or reaches hold pressure).

-

-

-

« Total Transfer Time »: Time from cavity pressure level reached until hold =

eDART reaction time + press reaction time + press response time

-

Click here for the next tip on Splitting the eDART Port Load for Speed