Tip of the Day 73: Stabilization with Cycle Values Template

Since we are on the topic of stabilization here is another tool that can help in addition to the Setup Notes tool.

One of the common problems in a plant is not only that the cavity pressures are not correct (not to template) but that the reason is often someone did not put the same process setup parameters into the machine. Or, in some cases, they did put the right parameters into a machine but the machine refuses to go to the same speeds or pressures that it should.

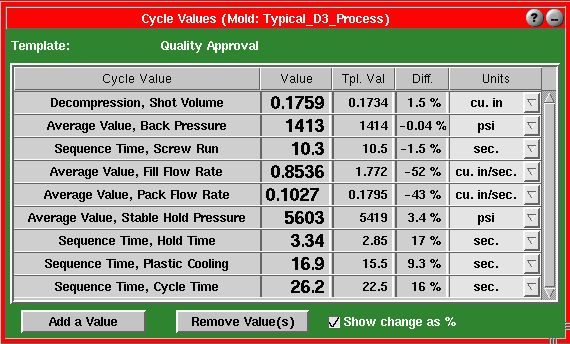

When you make a template the Cycle Values tool saves all summary values currently being computed as “Template Values”. You can then refer to these as a sort of process setup sheet. These parameters are “normalized” to volume and plastic pressure †. Here is an example of a cycle values window with its template values beside it. These are shown in the order in which you would probably set up the process (You can click and hold on a cycle value row and drag it up or down while it is colored light blue).

Notes:

- The values may be displayed as a percent difference or actual value by ticking or un-ticking the box at the bottom.

- You need to make sure that your sequence inputs are correct and that the fill volume is set correctly before saving the template. Otherwise some values may be missing or incorrectly computed.

- The Average Value / Pack Speed shown above only applies to 3-stage processes. If your process has more than 2 speeds.

Sequence Time / Plastic Cooling starts at the end of fill (fill volume as set by user or automatically) and ends at the end of mold clamped. You could also used Sequence Time / Mold Clamped but Plastic Cooling is closer to what the plastic actually sees. Sequence Time / Mold Clamped is a good mesure of how the operator set up the process.- The Average Value / Stable Hold Pressure is the flat area of the injection pressure curve during hold. It is a representation of the machine’s set hold pressure. You might also use Average Value / Hold Pressure. In many cases this second value closer to what the plastic sees because it includes an average pressure over the entire hold time. This includes any response time issues at the start of hold (e.g. oscillations or slow response).

Next Tip: Setting up default cycle values for all molds.

† We intend one day to present them “un-normalized” so that you can see what machine settings will be required to match the volume and injection pressure values.

Additional Information

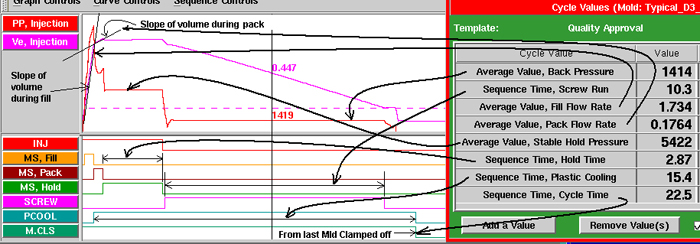

Here is a graphic showing where these values come from on the cycle graph for a decoupled 3 process. You may wish to substitute Sequence Time / Mold Clamped for Sequence Time / Plastic Cooling because relates more closely to the machine setup. But the cooling of the plastic actually begins at the end of fill so it more closely relates the plastic variable “Cooling Time” than does the mold clamped time.

In a D2 process the Average Value / Pack Flow Rate will not be computed because the process goes from fill to hold.