Tip of the Day 52: Temperature Stabilizes When?

As we study temperature more and more we keep finding out more cases in which we “don’t know what we don’t know”, as Zip likes to say. Here’s a case in point.

Most people consider that a few shots after a job is down are going to be rejects. Generally this is considered a problem of material degradation in the barrel. If the barrel holds only a couple of shots or less then it should clear out shortly. In release 8.0 of the eDART you can reject “N” shots after the machine has been down.

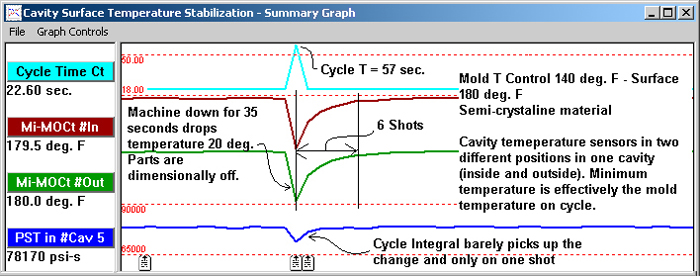

But in semi-crystalline molding with tight dimensional tolerances you can get a lot of change in the parts that is only a function of cavity surface temperature and does NOT show up in the pressure profile. In the following example the machine only stopped for 30 seconds but the temperature of the steel dropped 20 °F. This was enough to make the parts out of spec. But the cycle integral only picked up a change on one shot and that was within the normal alarm bands.

So how many shots should be rejected? Enough for the cavity wall to come up to the nominal temperature. Measuring this with a surface probe is problematic because the cavity wall looses its temperature before you can measure it (in the above case). The best thing is a cavity temperature sensor.

Lacking a temperature sensor the parts should be measured during the mold tryout. The machine should be stopped for a short time (as above) and a sequence of parts captured afterwards, labeled and measured. I think it would be wise to also stop the machine for a longer down time so that the mold surface approaches the temperature supplied by the temperature controller. Again, on startup, take a sequence of parts, label them and get them measured. This will inform you of how many bad parts to expect in both long and short down times. Then the “Reject after Down” can be set on the eDART’s Diverter Controls to throw away at least the required number of parts (and a couple more for good measure).