Tip of the Day 126: Was the part accepted or not?

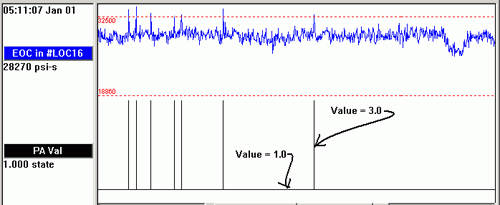

As I mentioned in tip #119, keeping all the data can be very valuable. If you are sorting parts for quality a part of the summary data is a number that indicates whether the Diverter Controls output was « Good » or not. Specifically, this value is called « Status / Part Alarm Value ». You can add it to the Analyzer’s or eDART‘s summary graph. It will look like simple square up-and down values. The number « 1.0 » is when the part went out with the diverter in the « Good » position. The number « 3.0 » is recorded when the diverter is in the « Reject » position and « 2.0 » for neither.

Here is an example showing the part alarm value in black.

It is important to understand that this value indicates the position of the Sorting Output contact closures for any reason. If you press the Diverter Control’s « Don’t Sort » and the parts are discarded, even without alarms, then the Status / Part Alarm Value is recorded as 3. If you have « Reject After Down » set up to throw away the first 7 parts after startup then those parts are marked as 3, even if the alarms show them good.

Thus if your customer wonders whether or not those parts got downstream into his shipments you can show him the data that proves certain parts were not kept.

Recall, though, an important point from tip #60, « What Happens After the Sorting Output? »: The data will tell you what the relay contact closure did. The down-stream mechanical and human processes must also be robust to prove that a part actually did get separated that was not good. For example an open conveyor or box for parts going to the customer is an opportunity for someone to pick up a part off the floor and set it there by accident.