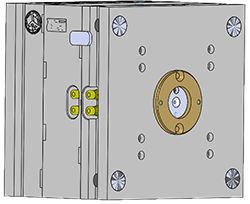

Mold Design for Injection Molding

Description du cours

Certificación Master Molder® I está diseñada para los técnicos de proceso, ingenieros o gerentes que necesitan entender y demostrar

This course provides mold makers, design engineers, and molders with the common language and core knowledge required to successfully design robust injection molds that meet cycle time, cost, part quality, and lead time requirements.

Class topics address good manufacturing practices (GMP) for part design, including fundamental material characteristics, necessary processing techniques, and molding non-conformities, with a focus on robust mold design.

Since hands-on-learning is a core component of our training, we will utilize industry examples as a reference, and then dive directly into evaluating and improving your designs.

Les temps forts du cours

Prérequis du cours

Part Design

- Wall Thickness

- Draft

- Radius

- Undercuts

- Surface Finish

Prints

- Tolerance

- Datum’s

Material

- Melt Flow Index (MFI)

- Shrink Rate

- Heat Deflection Temperature

Machine

- Clamp Unit

- Injection Unit

Processing

- Melt Temperature

- Flow Rate

- Pressure Gradient

- Cooling Rate and Time

Mold

- Line of Draw

- Steel

- Coatings

- Actions

- Gating

- Venting

- Support Pillars

- Cooling

- Ejection

- Instrumentation

Molding Non-Conformities

- Warp

- Short Shots

- Sinks

- Voids

Design for Manufacturability (DFM)

- Simulation

- Mold Design Checklist

None

| Start Date | End Date | Nom | Langue | Emplacement | Open Seats | Prix |

|---|