Tip of the Day 95: Protecting Manifolds (and Molds) with Injection Pressure Transfer

Syllogism:

a. Runner systems generally have large pressure drops.

b. Material viscosity variation varies those pressure drops

Therefore:

- Injection pressure transfer makes a poor way of controlling cavity pressure

- We do not promote control with injection pressure transfer.

- The injection pressure setting on the V to P Transfer tool on the eDART™ gets little or no attention

BUT…

Injection pressure transfer does have a purpose. Particularly in valve gate systems it is possible to create a condition where the machine is driving forward under speed control but all of the gates are shut. This can happen due to mistakes in setup or loss of air or hydraulic pressure to one or more valve cylinders. We recommend always allowing the machine to have adequate pressure to fill the part. This means that first stage pressure is usually set high to avoid pressure limiting.

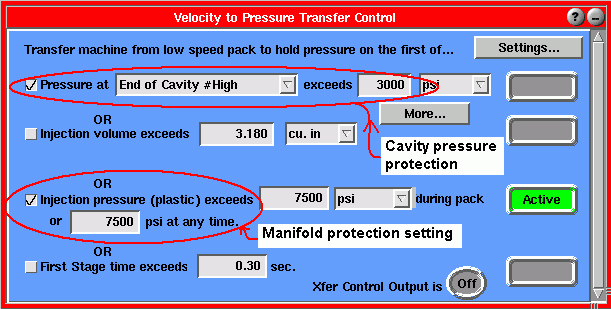

Suppose that you are using an eDART for V to P transfer of the machine (« external transfer » from the machine’s point of view). If you are using the eDART‘s valve gate control you should have V->P transfer hooked up and operating to stop the press when all the gates are closed anyway. The V to P Transfer tool has an option for transferring the press on injection pressure.

To protect the manifold set the « Injection pressure exceeds » value (at any time) to something less than the maximum that the manifold can withstand. Then the machine will transfer early if there is a blockage in the system or the gates are closed during the speed control phase on the machine.

Three more points:

- The first value for injection pressure, « during pack », will transfer the machine only if the injection pressure exceeds the set pressure after Machine Sequence / Fill (your set fill volume). This lets you set a lower injection pressure transfer during pack. For protection of the manifold just set them both to the same value.

- You should set the transfer pressure high enough to absorb any viscosity changes. For example if the peak injection pressure to fill the parts is running near 10,000 psi and you expect ± 10% material viscosity variation then at a minimum the injection pressure transfer would need to be set to 11,000 psi.

- This graphic also shows that cavity pressure is being used for protection inside the mold cavities rather than the manifold. A drop in viscosity could result in a reasonable manifold pressures while causing the material to flow too far and fast into the cavities and damage small features there.